Background

2,3-Butanediol (2,3-Butylene Glycol) is composed of three stereoisomers (Stereoisomers, 2R-3R-, 2S-3S- and 2R-3S-). Largely colorless and odorless, 2,3-Butanediol is a compound with strong hydrophilicity. 2,3-BDO is used as an intermediate in the cultivation process using biomass to produce high value chemicals such as Butadiene and MEK through the catalytic conversion process.

In addition, 2,3-BDO is an important industrial material that can be used as a food additive and a flavoring agent such as Acetoin and Diacetyl, plasticizers for thermosetting polymeric materials, and precursors of polyurethanes used in cosmetics and pharmaceutical industries. In particular, 2,3-BDO can be applied as a humectant in cosmetics and personal care materials. In the case of raw cosmetics materials or personal care products, 2,3-BDO assists in the development of natural ingredients rather than chemical synthesis. Processing techniques that maximize the efficacy of raw materials through the usage of technologies such as fermentation is actively underway.

Application

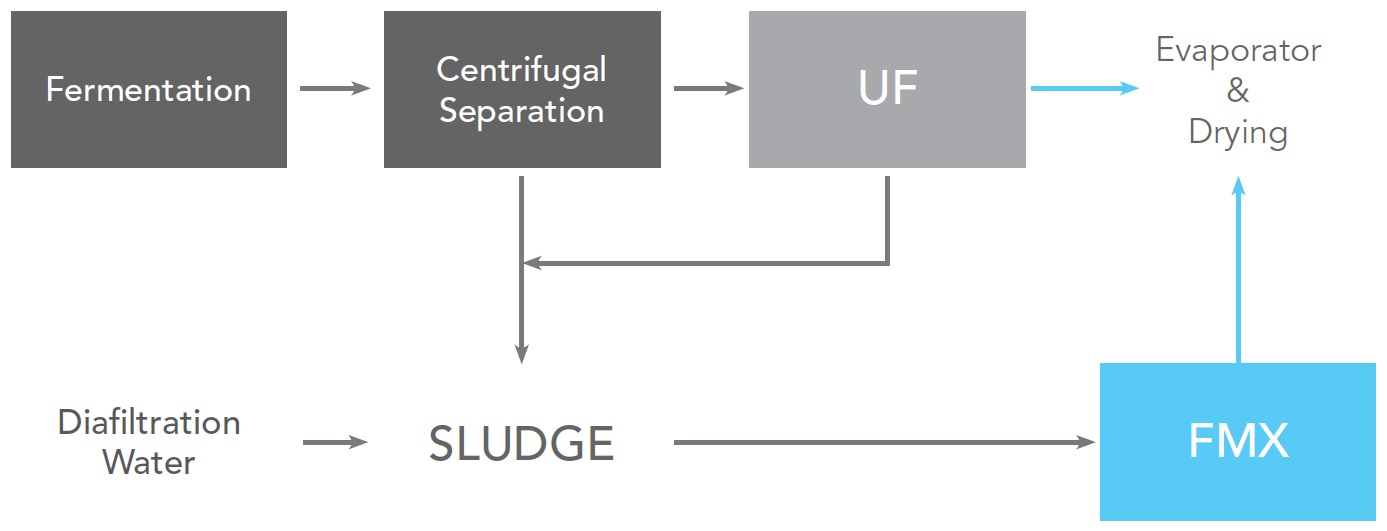

The conventional cell separation process used filter press with hollow fiber membrane, but it had low recovery rate and operating the facility proved difficult. In addition, when ED process was added after the separation process, the treatment efficiency was low due to impurities.

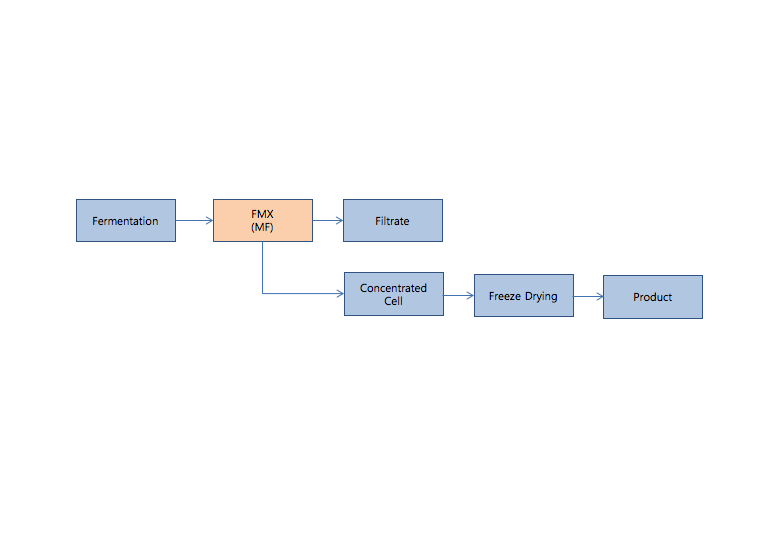

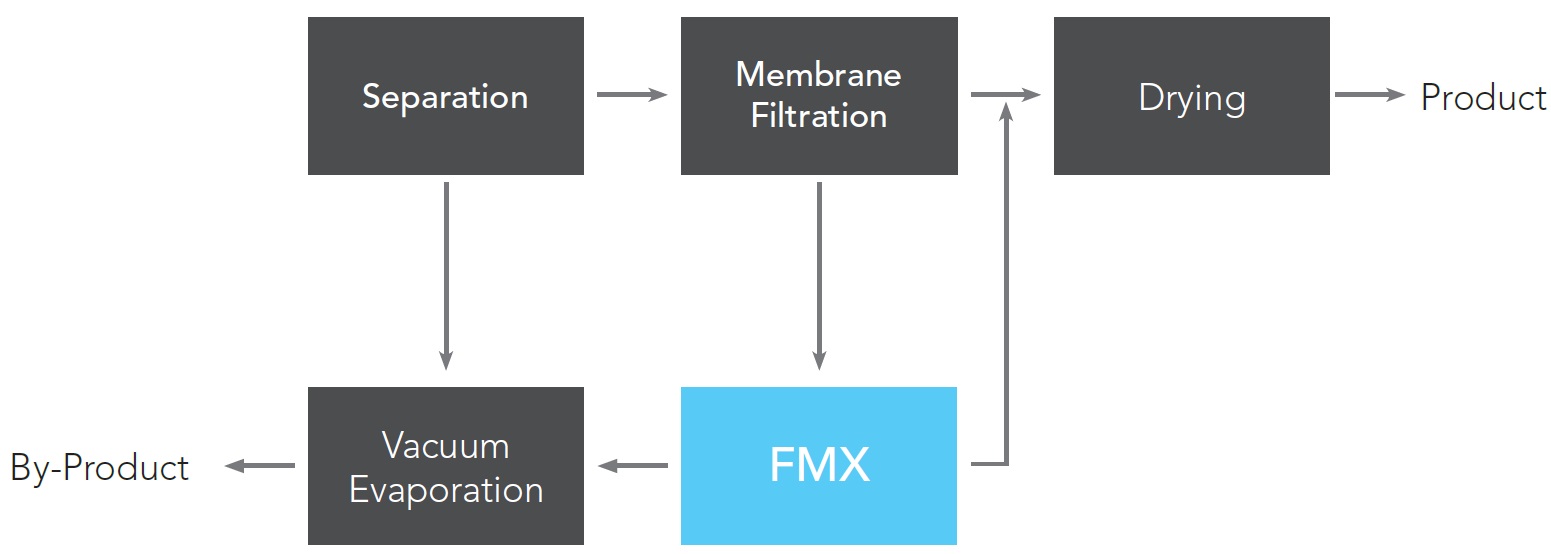

In order to solve this problem, FMX(MF) was applied to the culture broth and FMX (UF) was applied to protein and impurity removal. Figure 2 shows the separation purification process using FMX.

The Manufacturing Process of 2,3-BDO: Culturing Process -> MF/UF (FMX) -> ED(Electrodialysis) -> IEX (Ion Exchange) -> Distillation

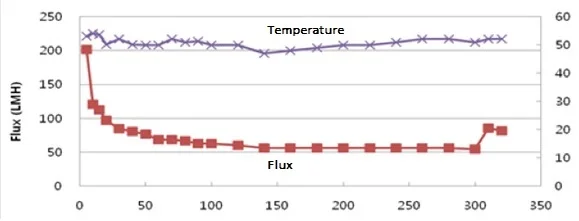

MF Process: FMX-E (MF) can reduce the facility costs by simplifying the existing filter press and hollow fiber membrane process. FMX process can also increase the recovery rate to 95% from the current recovery rate of 90%, increasing our client’s total production value by 300,000 USD per year. In the production of 2,3-BDO using bio-process, raw materials such as sugar, cassava, woody raw material, sugarcane are used.

The conventional filter presses’ recovery rate and process efficiency were affected by the type of raw material used in the process. On the other hand, FMX can achieve a recovery rate of 95% regardless of the type of material and 100% of the cells can be removed.

UF Process: FMX can be used to remove impurities such as sugar and protein, thereby reducing the load on the electrodialysis process (electrodialysis process time doubled, CIP cycle doubled). Higher recovery rates and reduced process times can increase product yield.