Turbo Blower (BKTurbo)

BKTurbo is a clean air generating turbo blower that ensures superior energy efficiency and performance. This revolutionary technology is developed from our extensive operating experience in over 100 Wastewater Treatment Plants (WWTP) worldwide. BKTurbo can provide a quick return on your investment by saving energy costs. Through the mitigation of carbon emissions, the blower helps sustain the natural environment. BKTurbo also contributes to a better working environment thanks to its oil-less operation and low noise levels.

BKTurbo's Low Energy Consumption

% Energy Use of Wastewater Treatment Facilities

"Blower systems account for more than 50 percent of a treatment facility's total energy usage. Waste & Wastewater treatment facilities spend 20% of the total electricity in California. They account for more than $500 Million total energy cost each year. Through the use of ENERGY-EFFICIENT EQUIPMENT, like turbo blower, energy concumption for these facilities can be reduced by 30%." (Southern California Edison, "Empower Savings Business Foresight", Second Edition, June 2010.)

Turbo Blower vs Roots Blower

Key Components

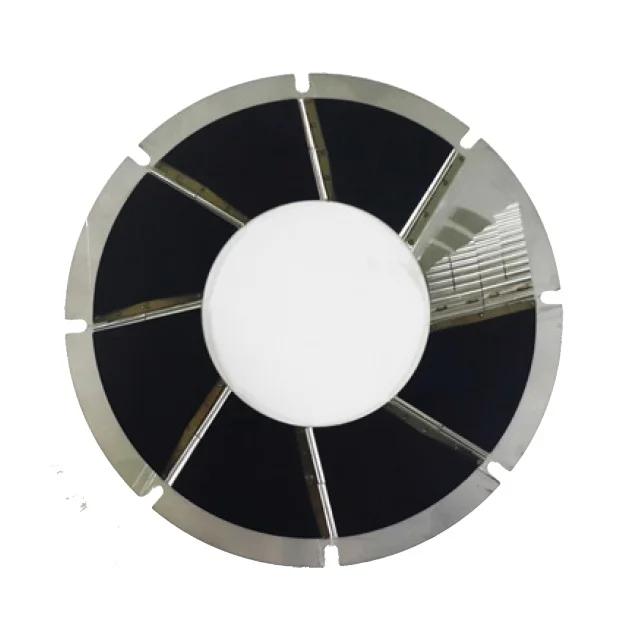

AIR FOIL BEARING

Since 2000, the air foil system has proven itself to be the most efficient and clean solution for high speed motor systems in heavy machinery. Today, air bearing is recognized as the best solution for high-efficiency and high-speed motor systems. The BKTurbo’s 100% oil-less air foil bearing system can supply pure air without mechanical friction, noise, or excess vibration.

Radial

Thrust

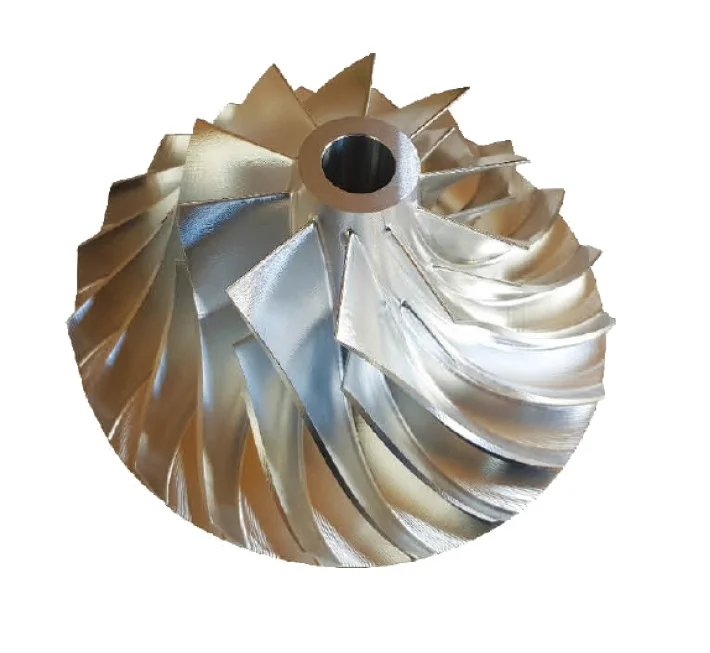

IMPELLER

The BKTurbo uses a unique aluminum alloy, tooled with 0.001mm precise machining, to guarantee high compression efficiency and reliability in all applications.

The impeller’s surface finish and hard anodizing coating enables it to maintain consistent quality and efficiency by resisting humidity and chemical exposure.

Furthermore, the impeller’s light weight also prolongs the durability of the air foil bearing.

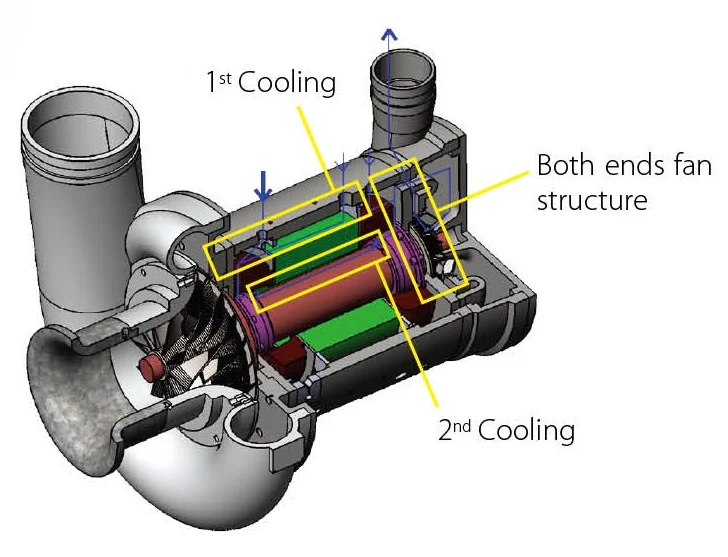

HIGH SPEED MOTOR

The BKTurbo motor is 95% more efficient than conventional AC motors. Specifically designed to avoid overheating in high-speed conditions, the BKTurbo’s PM motor is easily capable of continuous 35,000-hour runtimes by using a double cooling structure to maximize cooling efficiency.

Cooling the outside of the stator first, the motor then cools the outside foil bearing, winding, and rotor. Both ends of the cooling structure reduces stress on and increases the durability of the air foil bearing. Applied to all our products, this powerful cooling mechanism removes the need to install secondary or extra cooling systems, such as fans, inverters, and sine filters.

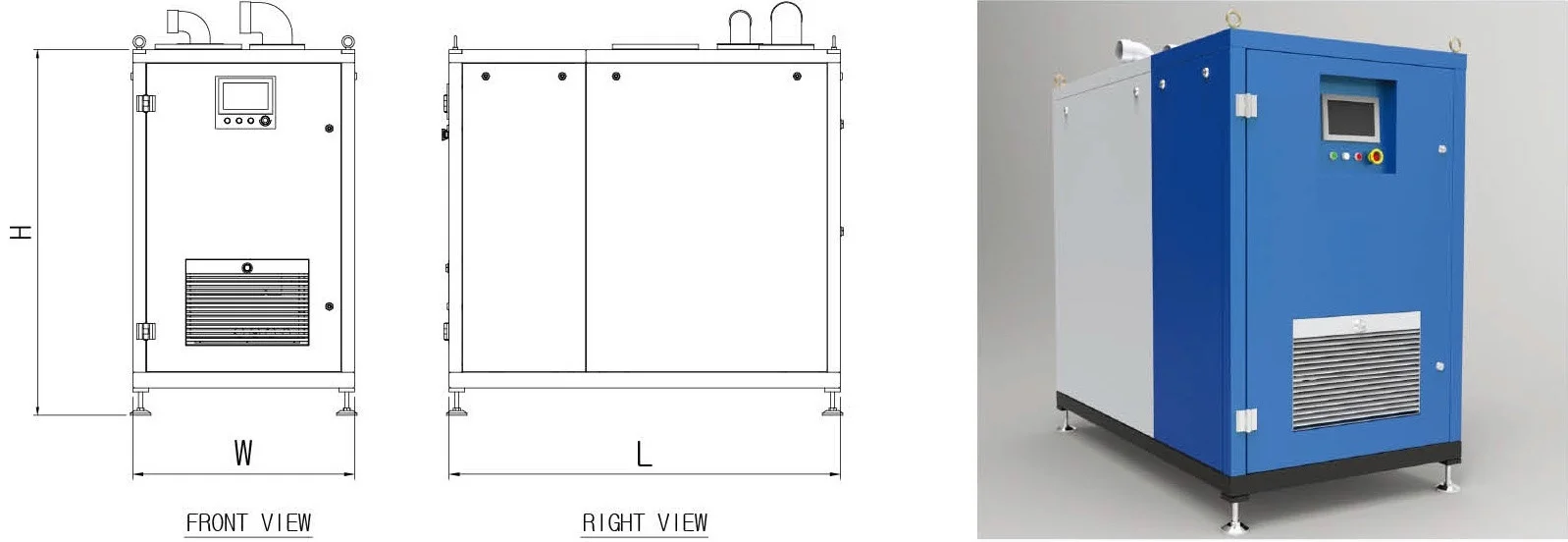

Dimensions & Specifications

| Dimension (mm) |

BKT30 | BKT50 | BKT75 | BKT100 | BKT150 | BKT200 | BKT250 | BKT300 | BKT400 |

| W | 700 | 700 | 850 | 850 | 900 | 900 | 900 | 1,200 | 1,200 |

| L | 1,300 | 1,300 | 1,500 | 1,500 | 1,800 | 1,800 | 1,800 | 2,200 | 2,200 |

| H | 1,100 | 1,100 | 1,400 | 1,400 | 1,650 | 1,650 | 1,650 | 2,000 | 2,000 |

| Weight (kg) | 600 | 600 | 720 | 750 | 950 | 1,000 | 1,050 | 1,300 | 1,500 |