FMX Applications

Food & Beverage Wastewater

Fish Thawing Water Treatment

Client: Fish Canning Facility, U.S.A.

Goal: Bacteria, micron and submicron organic particle removal, client would like to keep the thaw water useable for at least one week instead of the current 36 hour operation

Membrane: UF, 90,000 Dalton (FU-S400HB)

Average Flux: 160 liter / (m2 • hr) [94.1 GFD]

Note: Full scale recirculation flow rate of 3,000GPM (680 m3/hr)

Thawing Water: Feed (left) and Filtrate (right)

Winery Distillation Bottoms

Client: Commercial Winery, U.S.A.

Goal: Remove phosphorus and nitrogen from irrigation water

Membrane: NF

Average Flux: 64 liter / (m2 • h) [38 GFD]

Note: Concentrated water to be used as feedstock for anaerobic digester

Feed (left), Concentrate (center), and Permeate (right)

Grain Wash Process Water Treatment

Client: Commercial Brewery, U.S.A.

Goal: Concentrate grain wash water at 3% TS to greater than 12% TS so it can be used as animal feedstock. Reduce tipping fees associated with volume of grain wash water

Membrane: UF, 90,000 Dalton (FU-S400HB)

Average Flux: 124 liter / (m2 • hr) [85.7 GFD]

Note: Pilot study operated at high temperature (48 o C/118o F)

Wastewater solids removal: Feed (left), concentrate (center), and filtrate (right)

Beer Recovery from Trub Yeast

Client: Commercial Brewery, South Korea

Goal: Recover beer from fermentation bottoms

Membrane: NF

Average Flux: 10 liter / (m2 • hr) [6 GFD]

Note: Uniform RDF (*amount of sugar consumed) indicates the vortices do not harm the yeast (forced lysis)

Beer recovery from yeast: Feed (left), filtrate (right)

Bakery Wastewater Treatment

Client: Commercial Bakery, U.S.A.

Goal: Reduce and treat the water from wash cycle

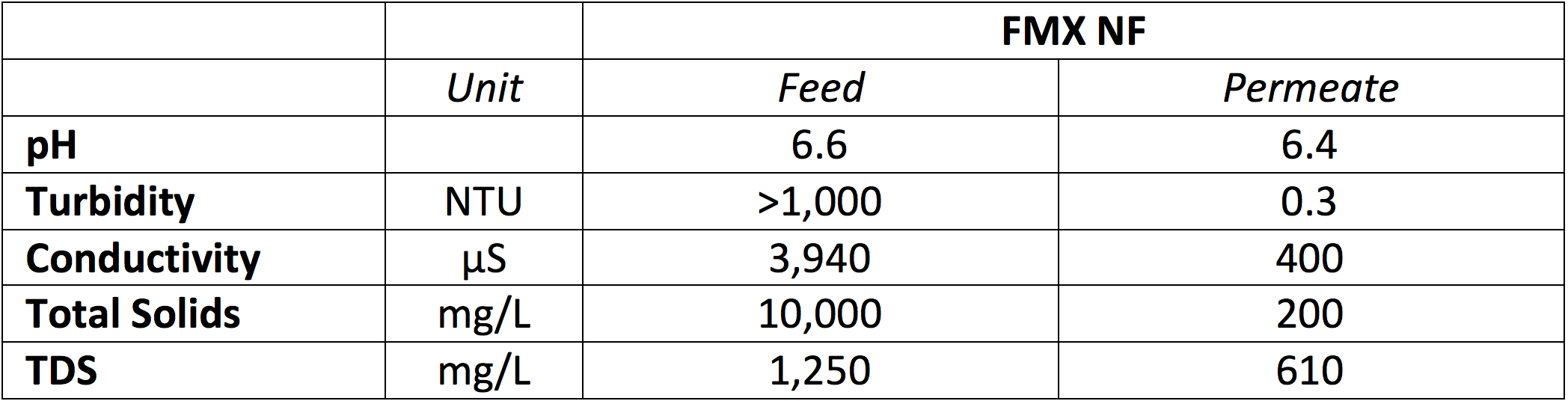

Membrane: NF

Average Flux: 90 liter / (m2 • h) [53 GFD]

Note: FMX helps prevent bio-fouling more than conventional membrane systems

Bakery wastewater: Feed (left) and Permeate (right)