Digestate contains abundant amounts of nitrogen and phosphorus, so a fouling-preventive membrane filtration system like FMX an ideal solution for recovering these nutrients effectively and efficiently.

BKT launched 20 years ago, bringing innovative technology solutions to the municipal and industrial wastewater industries. We have recently re-branded our water and energy business to Tomorrow Water. The BKT brand remains with a core focus on membrane filtration business with our patented membrane system, FMX.

FMX: Anti-Fouling Membrane Filtration

FMX is an anti-fouling membrane filtration system that was originally developed and adopted for Samsung Fine Chemicals in 2005. Samsung has continued to add additional FMX units whenever they expand their product line. They now have eight FMX units in full-time operation.

FMX is the go-to solution for solid-liquid separation, product concentration and resource recovery in manufacturing processes. FMX successfully separates the most challenging high solid, high density and high viscosity feed streams, delivering optimal resource recovery and saving costs for our clients.

Developed for customers who want to increase economical benefits by overcoming technological limitations, FMX is not suitable for every customer.

“We do not recommend FMX to customers who are satisfied with the current conventional membrane system.”

Our Stories: Failure to Success

Many companies want to hide their failures. At BKT, we have learned through years of experience that failure can be the catalyst for growth and improvement, and we have grown to befriend failure as a teacher for lessons we otherwise could not have learned.

Groundbreaking technologies are usually developed through painful processes and experiences. The successes from our past failures have taught us to anticipate problems in projects, to adapt to change, and to refine our strategies with the awareness that innovation is a result of growth through failure.

This is why we want to share some of our failure to success stories with you.

Biogas Plant MTI, The Netherlands

High viscosity digestate treatment

BKT’s experience in treating digestate with FMX membrane filtration began in early 2009 with Mosch Thermische Installaties (MTI), a specialized biogas plant in the Netherlands.

MTI had operated its biogas plant using tubular membranes and had tested ceramic membranes as an alternative for their high solid digestate with 10% total solids (TS). Neither membrane technologies were viable options due to extensive fouling, resulting in costly hauling expenses and membrane cleaning costs. In an effort to reduce operation and maintenance costs, MTI sought for a solution through BKT’s anti-fouling membrane filtration system, FMX.

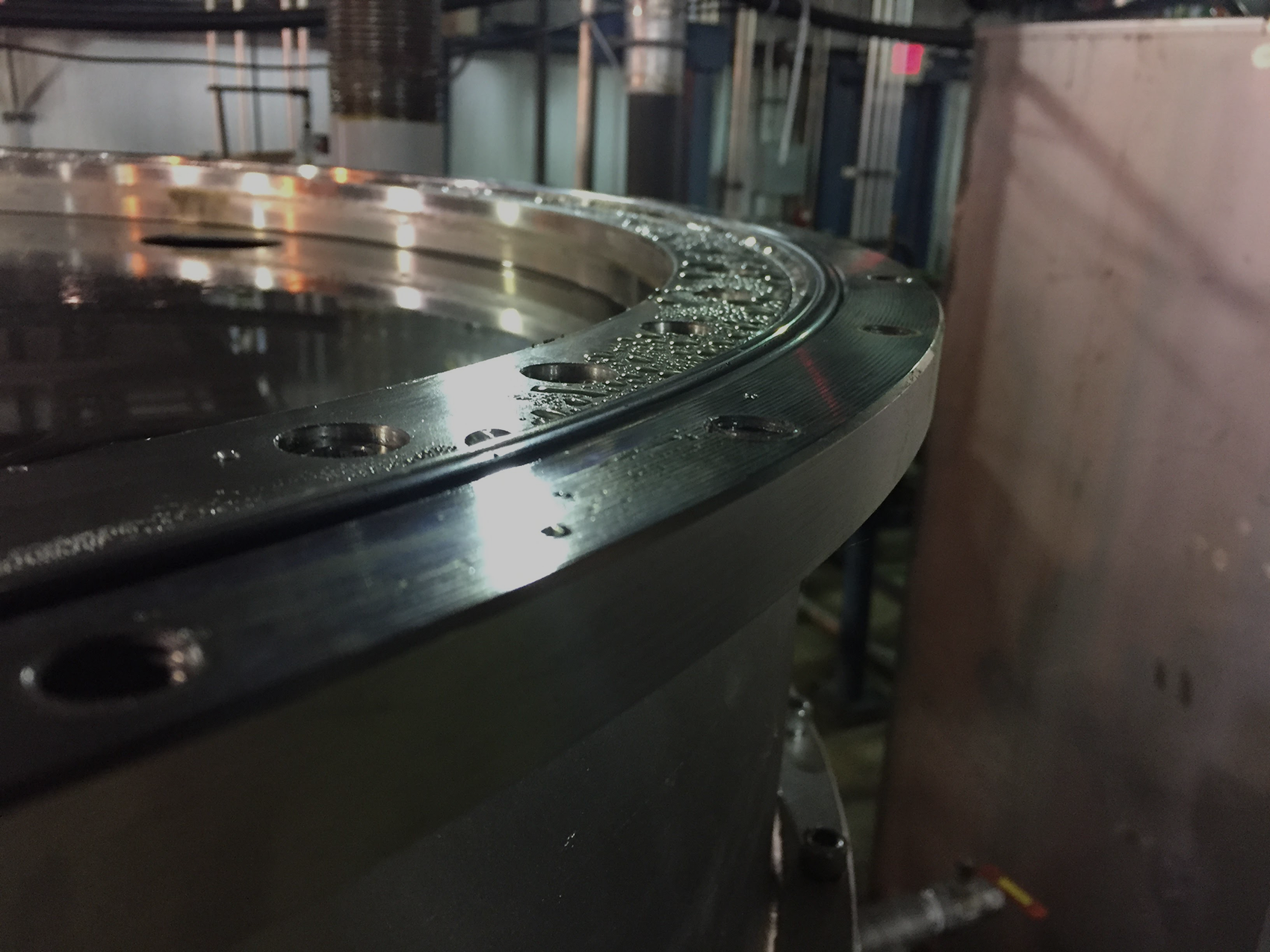

BKT installed three FMX S Class units to treat the high viscosity and high solids digestate (with glycerin, 3-4.5% TS). Along the journey, there were a few bumps in the road. Due to an incorrect control strategy employed in operation, the membranes were damaged as shown below.

Damaged Membrane

High Solids Digestate (with glycerin, 3-4.5% TS)

After the control issue was resolved, BKT devoted a task force to conduct six months of R&D to design more robust membranes to handle the high shear forces, streamlining and stabilizing FMX operations.

[EPTEE 2011] BKT to Present Membrane Filtration System 'FMX' (04.08.2011)

Three FMX units

Site Overview

Methylcellulose , Samsung Fine Chemical

Methylcellulose wastewater treatment

In 2002, Samsung Fine Chemicals tried to apply membrane filtration technology for its wastewater treatment plant and encountered major obstacles. Various membrane filtration systems were installed, but none were able to successfully treat the methylcellulose wastewater due to fouling, a reduction in throughput, constant membrane replacements and deterioration of mechanical reliability under the harsh operating conditions. Frustrated by the results with the significant amount of time and money spent, Samsung Fine Chemicals contacted BKT to see if it was possible to find a reliable membrane filtration technology. We accepted the challenge to create a breakthrough technology and the first FMX unit was installed in 2005. During the trial period of the first FMX, Samsung compiled a list consisting of more than 100 items that needed to be modified. BKT adjusted FMX per Samsung's requests and the resulting system became the basis for the current FMX. The vast improvement in performance are shown in the graphs below as provided by Samsung Fine Chemicals. The bottom graph is FMX performance data with four times the flux and very stable operation compared to the previously installed membrane system (the right graph).

FMX technology was able to generate increased revenue with the sale of by-products, while lowering wastewater treatment expenses. With an increased confidence in FMX technology by Samsung Fine Chemicals known to have the most stringent technical specifications, resulted in the purchase of 8 FMX systems. FMX systems continue to perform with consistent throughput and reliability, even though they are operating under extremely challenging conditions. In fact, the membranes from the first FMX system installation lasted 5 years, much longer than anticipated.

3, 4, and 5th units

6 & 7th Units

Colloidal Silica concentration

BKT installed the first FMX unit for a chemical company over three years ago. Our client needed FMX to concentrate colloidal silica for production. At first, the membrane in FMX would tear after operating 82 batches of colloidal silica. In order for the product to be cost- effective, our client needed to concentrate as many batches as possible before replacing the membrane. BKT made constant modifications, and 150 batches soon became attainable. As a result of continued efforts from both BKT and our client, FMX was able to produce more than 400 batches.

BKT took responsibility and dedicated resources and persevered in modifying FMX to guarantee that our client's needs were met. Committed towards consumer satisfaction, BKT was able to modify FMX technology to generate a higher yield, a shorter cyclic time and smaller footprint compared to the previous system used by the client.