CASE STUDY

COLLOIDAL PARTICLE CONCENTRATION | A Chemical company in Chicago

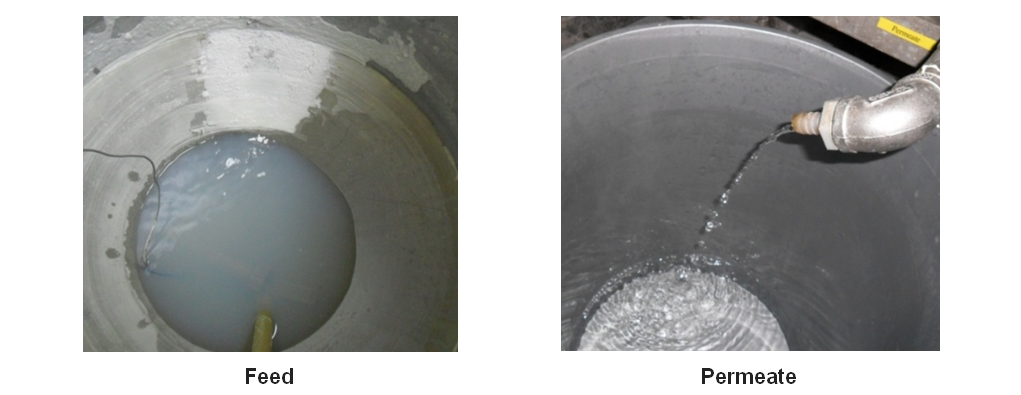

The typical production process uses conventional membrane systems or evaporators to concentrate the colloidal particles, but low production capacity, high operation and maintenance costs, and decreased ability to concentrate the particles caused a large U.S. chemical manufacturer to look for a new solution. The FMX was able to concentrate an initial colloidal particle concentration of 6%, to over 42% in the final product.

Is your conventional membrane systems concentration capabilities inadequate?

Increase it using FMX.

Many large chemical companies across the globe are involved in the production of colloidal particles to be used as a raw material in other production processes, such as for electronics. The typical production process uses conventional membrane systems or evaporators to concentrate the colloidal particles, but low production capacity, high operation and maintenance costs, and decreased ability to concentrate the particles caused a large U.S. chemical manufacturer to look for a new solution.

| Parameter | Units | Batch 1 | Batch 2 |

|---|---|---|---|

| Average Flux | LMH (GFD) | 120 (71) | 121 (71) |

| Initial concentration | wt% | 6% | 6% |

| Final concentration | wt% | 44.7% | 42.4% |

Pilot test results showed the FMX could not only achieve higher final product concentrations, but was also able to reduce fouling with the unique vortex system. The FMX was able to concentrate an initial colloidal particle concentration of 6%, to over 42% in the final product. During concentration the FMX can maintain a substantially higher flux when compared to the previous conventional membrane system, resulting in shorter processing times and lower operation and maintenance costs.

Recovery of Colloidal Particles in Concentrate Stream

FMX-S unit membrane assembly

FMX-S unit

Back to Applications